Industrial Hopper Liners

Industrial Hopper Liners

Mentor Dynamics has spent over 39 years becoming experts in the use of polymer materials in industrial hopper liners. Today, with the availability of more unique polymeric materials, UHMW-PE, and composite fabrications, we can provide complete solutions to your bulk material handling and storage problems through industrial hopper liners, chute liners and RAP bin liners.

Asphalt Plant Bin Liners

If asphalt production is reduced due to worn hopper walls or sticking material, maybe its time to consider lining your equipment with our Dyna-Flo® lining system. We have proven liner systems for your RAP Hoppers, Cold Feed Bins and RAS Hoppers. Mentor Dynamics has been servicing the asphalt plants and hopper manufacturers for close to 40 years.

Innovators in Industrial UHMW Liners

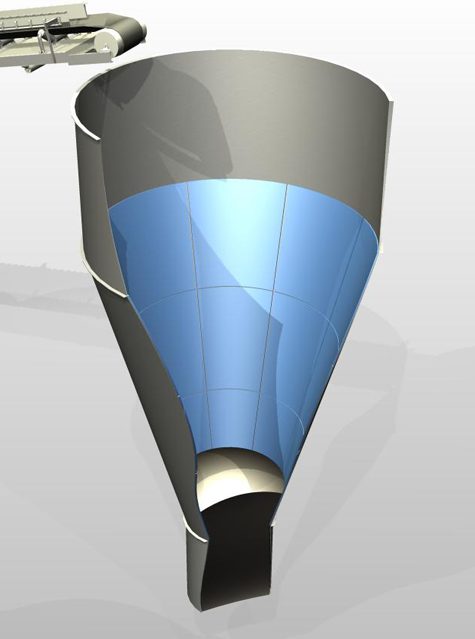

Until recently, fabrication of our Dyna-Flo® UHMW lining systems was limited to cut-to-size shapes. Now, Mentor’s new technology can be used to design and fabricate one-piece, drop-in, industrial hopper liners and chute liners including large sizes and complex designs.

Mentor Dynamics is also leading the way in the development of innovative fastener systems. Some of our new designs greatly reduce the number of fasteners required while other systems have completely eliminated the need for fasteners. These innovations allow quicker installations, better material flow, and improved industrial hopper liner performance.

With this combination of innovative technology, design knowledge and installation experience, Mentor Dynamics can provide you with an industrial hopper liner system tailored to your material handling and storage needs.

UHMW Bin Liners for Power Plant Applications

Our Dyna-Flo UHMW bin liner products have a thirty-nine year record of solving material flow and wear problems in industry applications. Our goal is to identify the root cause(s), which in industrial systems can be complex, and then design an effective solution. Frequently the solution may involve more than one material, or even other design considerations.

Three of our specially formulated polymers are shown below. Other more specialized products are also available. To determine the right material for your application, or to discuss additional application requirements, such as anti-static, UV, or steel filled materials, please contact us. We have worked with industrial operations across the country and will share our experience to help you select the right material for your operation.

A blend of recycled and virgin UHMW polymers. Low-cost UHMW Sheets with good material release and wear performance.

Applications

- Cold feed bin liners

- Aggregate hopper liners

- RAP hopper liners

Coefficient of Friction

85% lower than polished stainless steel. This material is not FDA-approved.

Color

Black or custom colors

Pure, 100% virgin UHMW Sheets which meet FDA compliance for use in food contact applications.

Applications

- Silo liners

- Hopper liners

- Conveyor shuttle liners

- Spouts and Chute liners

Coefficient of Friction

88% lower than polished stainless steel.

Color

White or custom colors

A premium, silicone filled, UV stabilized formulation. These UHMW Sheets are designed especially for improving the flow of difficult moving bulk materials.

Applications

- Pug mill liners

- Gypsum plant liners

- Sludge transport liners

Coefficient of Friction

92% lower than polished stainless steel. This material is not FDA-approved.

Color

Blue or custom colors

Industrial Liner Installations

Mentor Dynamics offers a range of installation options including turnkey by our trained crews; project supervision only or consultation; and prefabricated liner kits for those who want to do their own installation. Our installers are safety trained and comply with current OSHA and MSHA standards.

On your site or in our shop makes no difference to our skilled Installation Technicians. As Ambassadors of Mentor Dynamics, “perfection” is not a word but an action. Each of our skilled Technicians brings years of hands-on training to every project. Whether the Technicians are supervising the installation of a liner in a cargo hold of a bulk commodity ship in China, installing a coal bunker liner in Canada, or lining a transition chute in our shop; the job is not finished until excellence in workmanship is a matter-of-fact.

Increase Productivity & Efficiency

Along with 39 plus years of installation knowledge, we have the most know-how in the industry when it comes to designing, bending, forming and welding polymer materials into component parts. We utilize both traditional and “state of the art” design concepts and will recommend the one that provides the best performance for your application.

If you are still debating the merits of mild steel versus stainless, join the revolution by considering the latest polymer, UHMW-PE or composite materials and technology available from Mentor Dynamics. The Mentor team applies experience, knowledge and imagination to solve your productivity problems.

That’s why Mentor Dynamics is truly the solution Company leading the way through the industrial polymer revolution.